Well, a little late with this post, but better late than never!

The 2018 Results (finally) came in and as per my log submission and and checking all other online submissions, I did indeed come in at First place in 2018.

Onto this (last) year

During the period leading up to the 2019 Contest, I actually did little more than some minor (or not so minor) maintenance on various aspects of the Station and Antenna’s. I had a few repairs to make, made a few (undocumented) discoveries that really improved the station.

First off – Repairs – The 160M horizontal loop suffered a break, and when I put it back together, I found that I was getting all sorts of interference in the shack. With as little as 5W of RF on 160, the Computer was disconnecting from the Radio. So job #1 was to investigate.

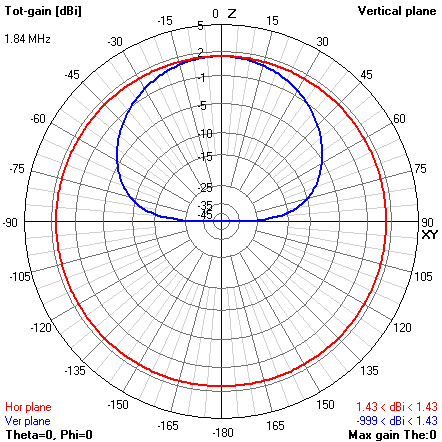

Like a lot of people , over the last year I had purchased a NanoVNA (every Ham needs one of these!) and ran a sweep over the Loop, only to find that for some strange reason it was nowhere near where it was last year! I spent ages checking, trimming and tuning the antenna and managed to get it sorted out and back in tune on both 160 and 80M. At this point, the RF in the shack was EVEN WORSE! and the PC connection was not usable to track bands for the logging software now down to 1W!. Given that this was the day of the OCDX, too bad, I had to live with manually setting the band in VKCL for logging.

I did in fact sort this out – and all it took was to actually install an Earth! Yes, Guilty, like probably a LOT of Amateurs, I had managed to get away without having a dedicated Station Earth. So a coupe of weeks after the OCDX, a standard 4 foot copper clad steal earth stake was banged into the dirt at a location where I could run a physically short earth wire to the TXCVR, and Voila, 100W on any band on the Horizontal loop and no Computer issues. I do suspect that I may still have work to do to work out why the RF was starting to get into the shack and I actually suspect that I have not been careful enough with the ladderline from the look and keeping it far enough away from metal allowing it to become un-balanced and actually radiating – more work to do so I ensure that I am not just dumping RF to dirt rather than radiating.

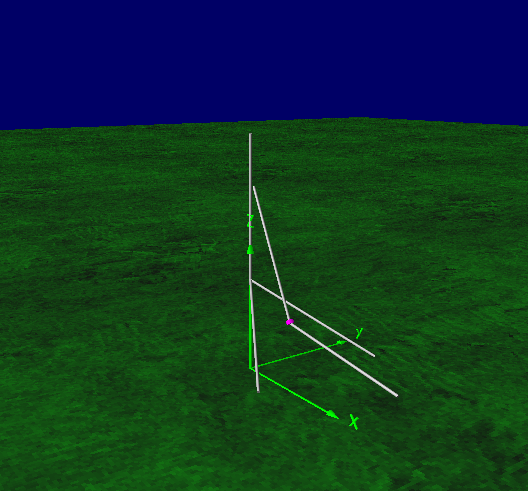

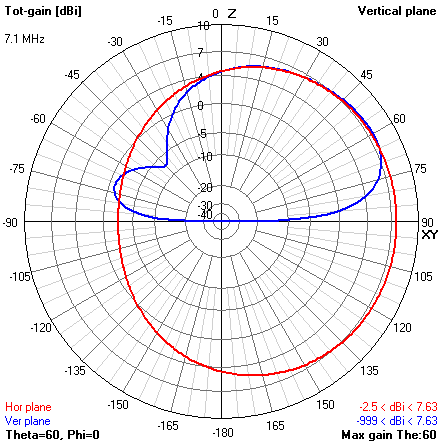

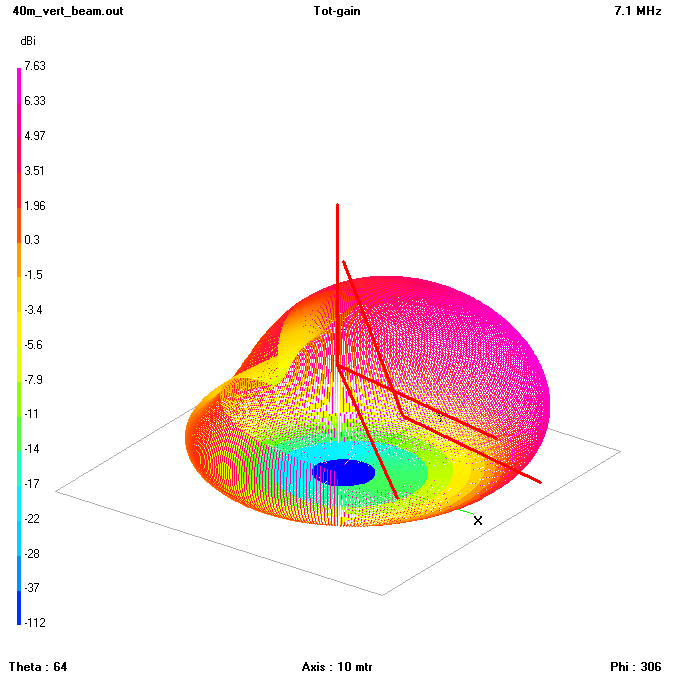

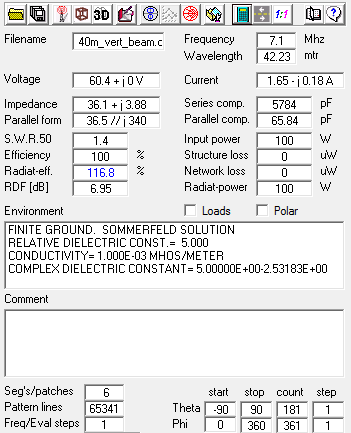

Now, the 2nd lesson for the year – the Gap Vertical Antenna. It had always been an awesome RX antenna, but I had never been very happy with it as a TX antenna, So back to basics here. A double check it was assembled, with the radials as per the instructions.

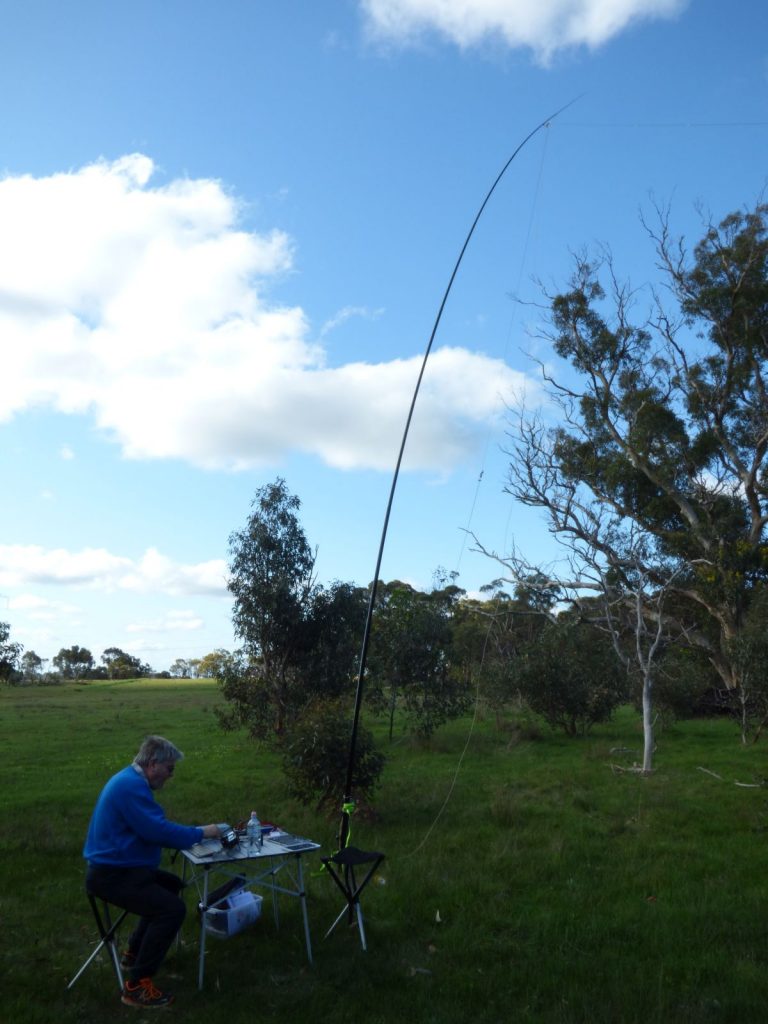

Assembly was fine, nothing had come apart. The Manual says at least 3 radials 25 feet long. I had 5 or 6 that were between 25 and 40 feet long and they were pretty ratty, and most had actually broken. So first off, replace the radials, with exactly 3, 25 Feet long and have them off the dirt.

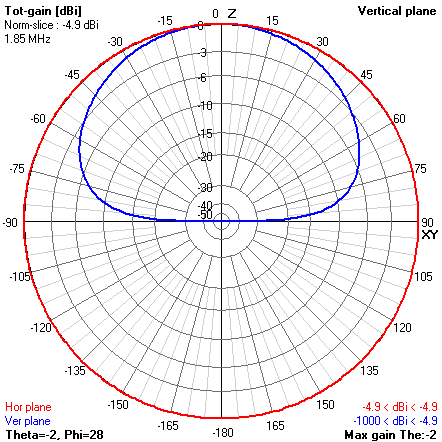

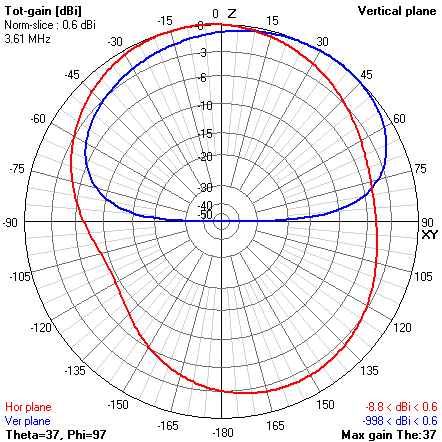

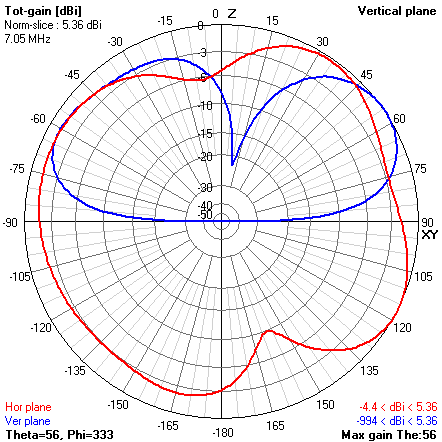

During the year in my reading one thing that I had never taken any notice of before was a comment regarding feeding Vertical Antenna’s – and while I was looking at this in terms of vertical 1/4 wave ground plane antenna’s and the Gap Is essentially a vertical Dipole, I did not think this next step was necessary – How Wrong I was!

The simple tip – Every single Vertical Must have an appropriate Choke at the feedpoint. I thought well, why not try this as well,

So, after looking around for the requirements of what makes a good choke, and that I needed to achieve at least 500 ohms (of course more is better) on the bands I was transmitting on to be worthwhile I settled on grabbing a FT240-43 core and with it wound with 13 Turns of RG-58 it provides at least 1K reactance across 80M to 10M.

At worst, this would do nothing, and I would be out the $ for the core, so why not.

Well, with choke at the feedpoint, and new elevated radials I threw the analyzer on the antenna.

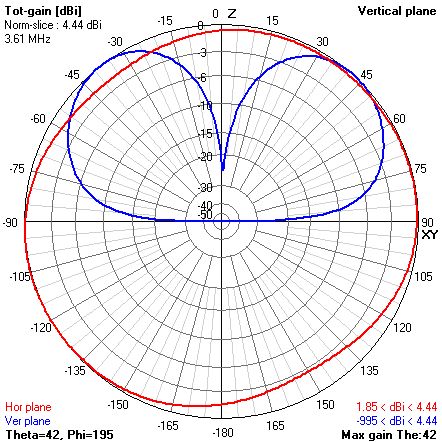

80M – was well out of band and all other bands (40-6) were just fine.

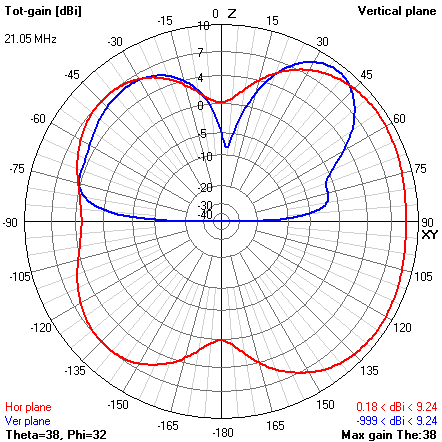

In the past, I was able to tune this antenna on 160 and 80, and all other bands were very close, and could be used without the tuner. I could no longer tune on 160 or 80, but the big surprise was using the antenna, On all bands it was still actually great as an RX antenna, but the big surprise was that it was now actually radiating and in the intervening time It has proven to be a great DX antenna!

I utilized this antenna almost exclusively for the high bands during OCDX 2018.

Yes, that coax, from the vertical across the ground was literally allowing me to match the antenna and was probably absorbing a very large amount of the RF. I just wish that The GAP manual actually had a comment in it that you in face NEED to de-couple the feedline from the Antenna.

Ok, finally, back to the OCDX 2018 – I worked it pretty hard and the conditions were even worse than 2017 when they were awful! Thank heavens that this is literally the dead bottom of the Solar cycle, and things should slowly start looking up in the next 1-2 years!

Again, operating QRP was a real challenge and every contact was hard-fought.

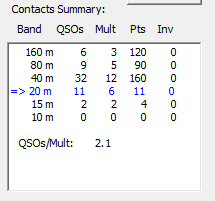

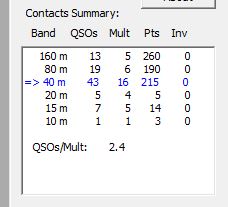

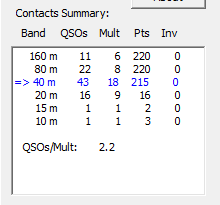

Not a lot of difference between 2018 and 2019, down on 20M, up on 15M and down on the multipliers.

I submitted a log and kept checking the log page for any other challengers to my score.

My Score as submitted is

| VK5HC | Single-Op ALL QRP | 25419 |

Yes, that is lower than last year and again, I feel I had better antennas than previous years.

Now, the waiting game until the official results are published. There is 1 other log that was submitted that was close to my score –

| YB3EDD | Single-Op ALL QRP | 23568 |

and the next closest was down around 13K. So the wait is on to see if my logs hold up and my score remains, if so, by a fairly narrow margin I may have done it again this year.